|

|

Camera Lucid Atlas ATX081S-UC

DescriptionFeatures:

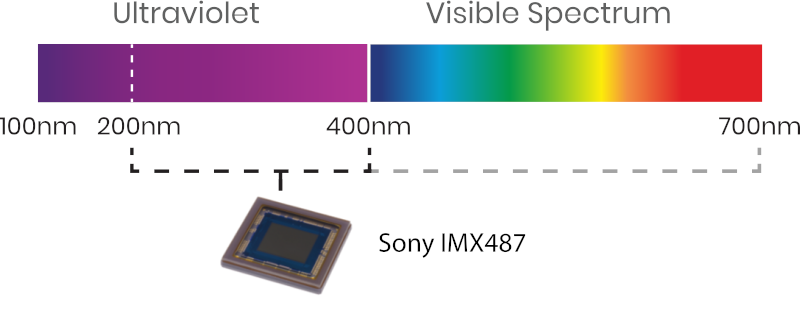

10GigE Ultraviolet (UV) Industrial Camera The Atlas10 UV 10GigE (10GBASE-T) PoE+ camera, featuring the high-sensitivity Sony UV 8.1 MP IMX487 sensor, is capable of capturing images across the ultraviolet (UV) light spectrum range (200 to 400nm). Utilizing Pregius S back-illuminated sensor technology the camera’s high sensitivity of the 200 to 400nm range opens up a world of industrial applications with greater precision in transparent materials (plastic and PET), semiconductor inspection, material sorting and more.

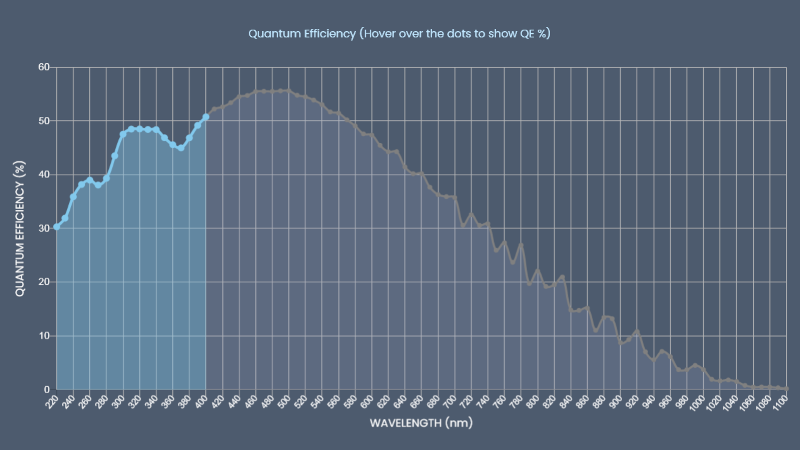

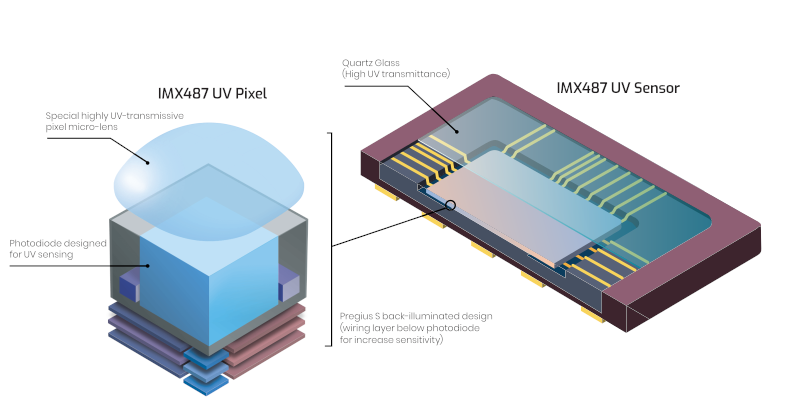

Industrial Features + High UV Sensitivity The Atlas10 UV is packed with industrial features designed to provide high speed and reliable operation in challenging environments along with excellent sensitivity in the UV 200-400nm range. Sony’s IMX487 CMOS sensor utilizes Pregius S back-illuminated pixel structure which moves the wiring layer behind the photodiode, allowing for increased sensitivity. This helps improve quantum efficiency, dynamic range, and lower noise. Combined with the camera’s industrial features, the Atlas10 UV provides high quality imaging for your advanced sensing application.

The IMX487 sensor is intended to be used within the UV range (200nm to 400nm). While the sensor is capable of sensing light beyond 400nm, visible light performance is not guaranteed and is instead shown below only as a general reference that a visible light cut filter is needed. The sensor and camera do not filter light beyond 400nm and a visible light cut filter (sold separately) should be used for best results.

Design for UV

UV Applications

Wafer / Semiconductor Inspection

Recycling Sorting

Power System Inspection Technical specification

DocumentsSoftware |

|